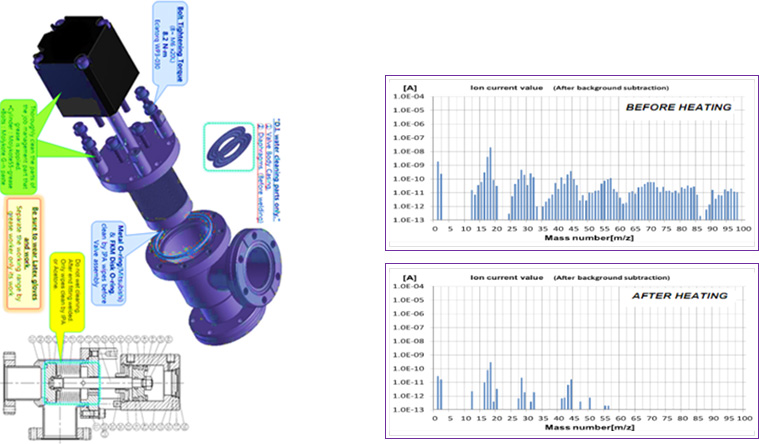

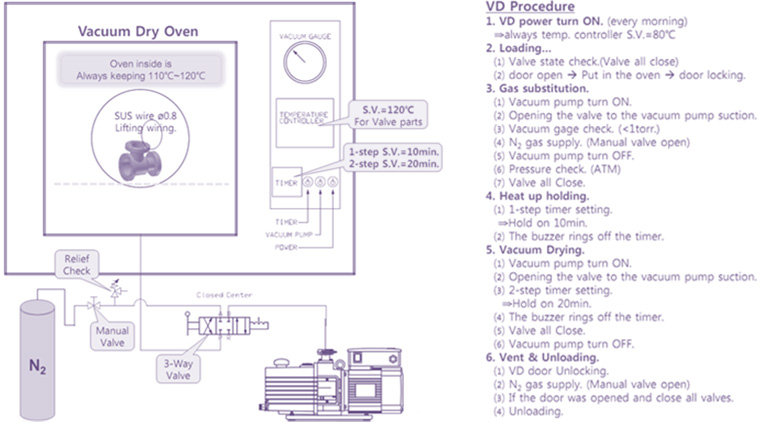

We process ultra high vacuum angle valves additionally by baking them separately. This applies to two types: welded metal bellows ass’y and angle body according to our vacuum drying facilities and procedure.

We offer clean products suitable for higher-level vacuum environments. Interior cleaning of back out processed

products -please refer to the mass spectrum graph below.

The ion current value has noticeably decreased, demonstrating higher suitability for high-vacuum environments.

Managed by our product quality team, this product applies a higher standard than other products when it comes to interior surface and the condition, pollution and moisture minimization of welded beads. During the interior cleaning process,

lubricants including vacuum grease are not used and exposure is only to stainless steel

(there is no contact to other metals such as aluminum).

Our ultra high vacuum pipes are manufactured for the

ideal vacuum level. By transferring heat via cylinder,

the problem of shortened life span is solved for

high-temperature heating valves.

We adhere to internationally recognized measurement

standard of ISO/TS 3669-2 for cleanliness management

as well as measurement of bakeable CF flange.

(external diameter, bolt hole, pitch-diameter)

Compliance with Restriction

of Hazardous Substances

Machining and

material management

Welding quality standard

and manufacturing method

Data management

View moreCleaning and

clean management

Cleaning and

clean management

Bakeout process

View moreProduction activities

View moreProduction environment

View moreLeak inspection

procedure and stadards