To facilitate smooth, efficient production, we only manufacture most of our products inside the clean room and guarantee an efficient

manufacturing environment with expert staff assigned by product category.

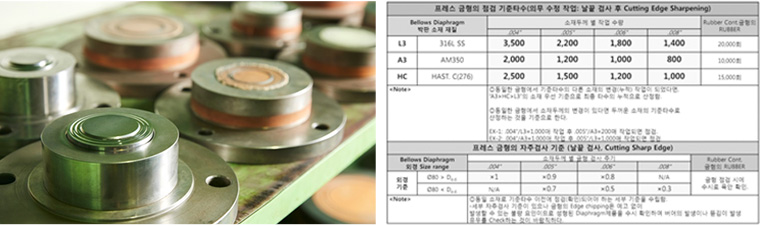

We pride in our metal mold design expertise but also various types and sizes of metal molds. Among metal molds and ZIGs,

welded metal bellows’ sheet pressing metal molds require precise design, manufacture and management.

We are able to predict quality decline by recording and managing the number and time period of production according to the

metal mold’s serial number.

By taking proactive measures against these predictions, we are further able to prevent quality problems. Because this is directly

linked to the product’s quality, price and competitiveness, only our experts are delegated the task of design and management.

Smooth supply of materials is a key aspect of the

manufacture environment, for which we have

installed the material cutting machine.

This secures our products’ competitiveness by

reducing time, cost and manpower incurred during

the ordering and warehousing of materials under

general machine processing.

Compliance with Restriction

of Hazardous Substances

Machining and

material management

Welding quality standard

and manufacturing method

Data management

View moreCleaning and

clean management

Cleaning and

clean management

Bakeout process

View moreProduction activities

View moreProduction environment

View moreLeak inspection

procedure and stadards