We have consistently invested in implementation and

manpower, the most important factors for a manufacturer.

Expert engineers create consistently high quality products

when it comes to the most basic machine processing and

welding. Because minute quality changes directly affect

micro welded products’ life span and performance,they

require perfect product management, and for this reason

we have selectedtheautomatic manufacture method.

The welded bellows manufacture method we have selected

both produces and 100% automatically inspects errors

of approximately 1/100mm in perimeter of the welded bead.

This makes possible the highest quality control. In addition,

any defect deviating from the quality standard during the ma

chine manufacture process is recorded, reported and

managed within 24 hours. We are experienced in manufactu

re and processing of various metals, alloys and other

materials including Sus304, Sus316, hastelloy, aluminum,

Inconel, copper, and Ultem. Also, we drive the best results

by substituting and/or modifying related materials.

Our in-house seasoned experts also creates the buff polish,

important for the exterior. We continue to investandlead

high-quality production and competitiveness.

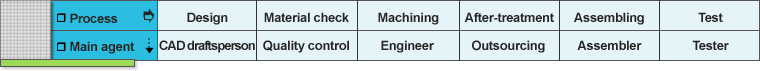

All our products adhere to set labor and production standards, and we process our products in-house except After treatments.

Compliance with Restriction

of Hazardous Substances

Machining and

material management

Welding quality standard

and manufacturing method

Data management

View moreCleaning and

clean management

Cleaning and

clean management

Bakeout process

View moreProduction activities

View moreProduction environment

View moreLeak inspection

procedure and stadards