To minimize deformation from welding, we use optimal ZIG.

Products requiring high precision are processed a

secondary machining (No.45867850) to correct for any

deviation from the target measurement. In cases of

highvacuum environment, we use the back bead welding

process to manufacture vacuum pipes.

To prevent oxidation and minimize outgassing, we weld only

after nitrogen charging.

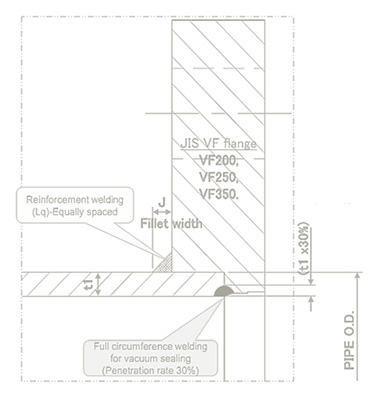

We use different welding processes depending on the

environment and characteristic called for.

Smallcaliber ports connected to vacuum pipes are

relatively weak to physical force. We resolve this by

testing tensile strength.

We adhere to the manufacture, management and

inspectionstandards for vacuum welding.

We check the interior welding status, which is the most

important part of vacuum pipe quality control.

We focus not only on the exterior condition of our

products but also the interior, which directly affect

product performance.

□ Back bead

□ Autogenous

□ Fillet

Compliance with Restriction

of Hazardous Substances

Machining and

material management

Welding quality standard

and manufacturing method

Data management

View moreCleaning and

clean management

Cleaning and

clean management

Bakeout process

View moreProduction activities

View moreProduction environment

View moreLeak inspection

procedure and stadards